AN INTRODUCTION TO BARCODES

Introduction

You can use barcodes and bar-coding without being an expert on the technology. But understanding a few key points will help you make better decisions when it comes to selecting and implementing a solution in your business.

How Does A Barcode Work?

When data is displayed as a barcode, each character is represented by a pattern of wide and narrow bars. A barcode reader uses a photosensor to convert the barcode into an electrical signal. The scanner then measures the relative widths of the bars and spaces, translates the different patterns back into regular characters, and sends them to a computer or portable terminal. Every barcode begins with a special start character and ends with a special stop character. These codes help the reader detect the barcode and figure out whether it is being scanned forward or backward.

Some barcodes may include a checksum character just before the stop character. A checksum is calculated when the barcode is printed, using the characters in the barcode. The reader performs the same calculation and compares its answer to the checksum read at the end of the barcode. If the two do not match, the reader assumes that something is wrong, throws out the data, and tries again.

Why Would We use Barcodes?

Barcodes allows for the automation of business procedures. This increases productivity and reduces human error. The most common use of barcodes is to find and track products as they are moved around a warehouse.

Barcodes could also be used in other settings, for example data-entry. Instead of manually typing customer identification numbers into a database, for example, a data entry operator could use a barcode system to simply scan in the information.

What Is A Barcode Symbology?

A barcode symbology is not the same as a bar-coding standard. Every barcode standard uses a barcode symbology but two standards such as EAN13 and UPC14 can use the same symbology.

There are different barcode symbologies, each with their own particular pattern of bars. The EAN/UPC code used on retail products is an all-numeric code while Code 39 includes upper case letters, digits, and a few symbols. Code 128 includes every ASCII character code.

At Afrisoft, we generally use Code 39 as the symbology for barcodes for internal use because it is a robust and compact symbology. Code 128 tends to require more space on a barcode.

What Barcode Standard Should I Use?

Selecting the right bar code is critical to the success of your bar code implementation plan. Here are some high level points to consider:

- Are there any industry standards that your codes must conform to, or is an important customer insisting on a specific label format?

- Use EAN-13 for retail products (EAN-8 is a special variant for small products). This is based on UPC symbology.

- For bar codes with variable information like serial numbers, expiry dates, or measures, use GS1-128 (previously EAN128). GS1-128 uses the Code 128 symbology. The barcodes use a series of Application Identifiers to include additional data such as best before dates, batch numbers, quantities, weights and many other attributes required by the user.

- For labelling pallets or outer packaging that will be scanned by third parties, use EAN 14, which is also based on UPC symbology. The EAN/UCC-14, also called U.P.C. Shipping Container Code, is a 14-digit number assigned to fixed-content shipping containers. The first digit, the indicator digit, can be "0" to "8" and indicates a packaging level and "9" a variable measure item. There is however, no worldwide consensus on which number indicates which packaging.

- A single retail product will need an EAN13 code (i.e. a can of coke is one EAN13 barcode, a sixpack is another and a carton a third). However an EAN14 code can be used for a pallet.

- For internal use, any type of bar code can be used. If you ever need to encode letters as well as numbers, Code 39 or Code 128 would be a good choice. If you only need numbers, Code 39 is very robust and also compact for numeric data.

What Is A 2D Barcode?

2-Dimensional symbols are generally square or rectangular patterns that encode data in two dimensions. The primary advantage of 2-D codes is the ability to encode a lot of information in a small space. 2-D symbols can encode from 100 to about 2,000 characters, compared to roughly 20-25 characters for a standard barcode. A good example of a 2D barcode is the South African driver’s license. All the information on the license including the photograph and fingerprint is encoded into the barcode.

How Do I Get A Retail Barcode For My Product?

If you are selling products you will probably need an EAN-13 code. These numbers are assigned by registration authorities in most countries; you can find the EAN authority for your area at http://www.gs1.org.

Data Integrity?

Integrity of data is critical when using barcodes. If information is incorrect, the whole system will collapse, regardless of how accurately it is captured. This is often ignored when barcodes are implemented. It is dangerous to assume that as long as all items have a barcode label, the warehouse is ready to implement a scanning system. A barcode audit is well worth the time and effort. One simple way to do this with TransLution is to scan the barcode and configure the scanner to display the product description and/or stock code on the scanner. The user can then confirm that the description matches the scanned item, before moving on to the next product. A few days spent on an audit can save endless time and heartache later.

What Information Should I Put In My Barcode?

If you are not driven by third party considerations, you will be able to choose between various barcode design options.

For serialised items, for example, you could either opt for a barcode that contains both the item code and a serial number, or for simply securing a serial number to each item. In this case, reading the barcode will tell you nothing about the item, but in the database this serial number can tell you the stock code of the item, its current location, when it was scanned and even its movement history.

If you are dealing with products packed onto pallets you can use a similar system by creating a barcode for a pallet that just looks like a number, but once scanned can show you details for all items on the pallet. Moving the pallet then means scanning one barcode rather than every single item.

Do I Use a Stock Code As A Barcode?

With TransLution, there is no need to use your ERP stock code as your barcode, because you can link any barcode to a specific stock code (although you cannot link two different stock codes to one barcode).

If you are implementing a new bar-coding system, and if you already have barcode labels on your warehouse items that do not match your stock codes, then this feature is very helpful because it does not require re-labelling of stock. However, if your items are not already labelled and your stock code numbering system is accurate and robust, then using the stock code as the barcode is arguably a good idea, because it is simpler and removes an opportunity for data integrity to be compromised. If your stock code numbering is not very robust and stock code numbers end up being effectively text descriptions of 30 or 40 characters with spaces and other characters, then using them as barcodes is probably not a good idea. This just leads to barcodes that may be too long to print on small labels. Under these circumstances using barcodes starting at 01 and incrementing numerically may be a better option.

Should We Embed Quantity In A Barcode?

It is possible to have a barcode that includes a stock code and a quantity, so that when scanned, it tells the system how many items are being moved without the operator having to do this separately. This sounds like a good idea that will save time and reduce errors, but, like many ideas of this type, needs to be approached with caution. If the intention is to pack a small product, for example washers, into bags, and to label each bag with the number of washers in the bag, then the entire implementation has to be designed such that washers are never unpacked from the bag. If they are, the bag label must immediately be destroyed and a new one reprinted with the new quantity on it. This is very often not possible, illustrating seemingly good ideas are not suitable for all implementations.

Scanning Barcodes

Contrast

The contrast between bars and spaces in a barcode is always a potential problem area. For the best possible scan, all the bars should reflect no light at all and all the spaces should reflect 100%. In practice this never happens, however barcodes will still be scan-able, providing certain limits are not exceeded.

Black bars and white spaces are best. Some other colour combinations produce good scans, while others definitely do not. Most scanners use red light; therefore any colour that reflects red light is suitable for spaces and any colour absorbing red light is needed for bars.

Shades and hues can vary, but here is a general guide on what can be used:

Good Bar Colours: Black, Green, Blue, Dark Brown

Good Space Colours: White, Red, Yellow, Orange

Also, make sure the material is not too glossy or light reflection will obscure the scan.

Nominal Height

The data contained within the bar code is read by moving a spot of light across the barcode, starting in the white space before the first bar and moving through all the bars and spaces to the white area at the other end of the code. If the spot of light moves off the edge of the code during the sweep, the code will not scan correctly.

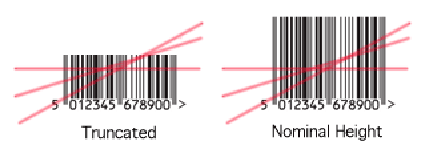

The wider the code, the greater the chance of the beam going off the top or bottom before scanning the entire width. It is obvious that by increasing the height, the chances of a good scan are improved. For this reason, most bar-coding specifications use a magnification factor which is expressed in percentage terms. For each magnification factor there is a nominal height, so that the width of the barcode increases in line with the height, maintaining scanability. In working practice, truncation (the reduction in height of the code without a reduction in width) is used. Care should be taken when truncating as scanning may be impaired.

White Space

Verify that enough white space has been allocated before and after the barcode. For most barcode types, the left and right margins need to be at least 10 times the X dimension to obtain a proper scan. In barcode technology, the X dimension is the narrowest part of a barcode’s symbology.

The X dimension is used to determine a barcode’s density, which is the amount of information that can be captured in a barcode within a specific amount of space. Other elements of a bar code are expressed as multiples of the X dimension. For instance, to ensure accurate scanning, most bar codes have a quiet zone with a width of 10X, or ten times the bar code’s X dimension. In general, the greater the X dimension, the easier it is to scan a bar code.

Conclusion

A clear understanding of how barcodes function will help you make the technology work for you and your organisation. Take the time to understand the options now and you will see the benefits in your business later.