SCANNING & LABELLING CASE STUDY: Praga Technical

Project Background

Praga Technical (Pty) Ltd has been serving the South African automotive industry for over 31 years. Praga Technical operates from a 24 000m² site in Pretoria consisting of six factories which manufacture, assemble and deliver high quality sheet metal components and a variety of assemblies and sub-assemblies to the automotive industry.

Ford Motor Company of Southern Africa (FMCSA), a customer of Praga Technical, requires that suppliers comply with new regulations for electronic data exchange and labelling of products shipped to them. Praga employed TransLution™ Software and the implementation skills of TransLution™ Africa to meet these requirements within the Ford prescribed deadline.

Project Objectives

The key requirements for the project:

- Praga Technical needed to be 100% certain that shipments to FMCSA accurately matched Fords’ production requirements.

- All items shipped needed to be clearly and accurately labelled per the Ford labelling standard.

- Electronic data exchanged between Praga Technical and FMCSA needed to be automated and in compliance with Fords’ requirements.

The project was launched early in June and was complete and deployed to production 1 September.

Translution™ Functionality

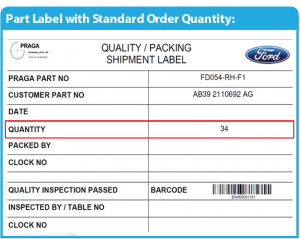

TransLution™ software generates uniquely designed barcode

TransLution™ software generates uniquely designed barcode

labels for goods manufactured by Praga Technical for FMCSA.

The labels are designed to meet Fords’ exacting standards

and are scanned as a part the picking and packing process for

orders from FMCSA.

How it Works

Praga Technical receives an electronic communication (DCI) from Ford informing them of the components to be supplied each day. The DCI information is imported by TransLution™, a Daily Requirement file is created and a Daily Requirement Report is printed to be used as a guide to assist in picking.

The Daily Requirement Report can be refreshed at any time during the day to show only what has been ordered and not yet picked and scanned for shipment. Items are picked from stock in standard shipping quantities and are placed in customer bins awaiting validation. The customer bin quantity is scanned and validated against the Daily Requirement to ensure the correct quantity for each item is picked and binned and awaiting loading when the trucks arrive.

The Daily Requirement Report can be refreshed at any time during the day to show only what has been ordered and not yet picked and scanned for shipment. Items are picked from stock in standard shipping quantities and are placed in customer bins awaiting validation. The customer bin quantity is scanned and validated against the Daily Requirement to ensure the correct quantity for each item is picked and binned and awaiting loading when the trucks arrive.

Once validation to the Daily Requirement is successfully passed, TransLution™ automatically creates and posts a dispatch note in SYSPRO and SYSPRO invoices the item and prints the invoice. Ford requires the full quantity for each item shipped have a unique invoice number which is used to create an Advance Shipment Notifi cation (ASN) label in their required format.

After the invoice has been created, new Ford part labels are printed by TransLution™ and applied to the product in the customer bin including the Ford ASN to allow for each item to be properly tracked and identified. When a truck arrives at Praga Technical, a load file is created in TransLution™ and the validated items from the customer

bins are scanned onto the load. After all the items have been scanned onto the truck and the load is completed,

TransLution™ creates an ASN file which is immediately submitted electronically to Ford. Sending the ASN to Ford

when the truck departs Praga Technical ensures ASN data for all products on the load will be available for receiving by Ford when the delivery arrives.

Accuracy, efficiency, ERP integration and meeting customer’s exacting requirements was facilitated by TransLution™ on behalf of the client.

Benefits

The key benefits offered by the use of TransLution™ software are that Praga is ensured that all shipments accurately match the Ford production requirements, all items are clearly and accurately labelled as per the Ford labelling standard, and finally that all electronic communication is in place as per the Ford standards.