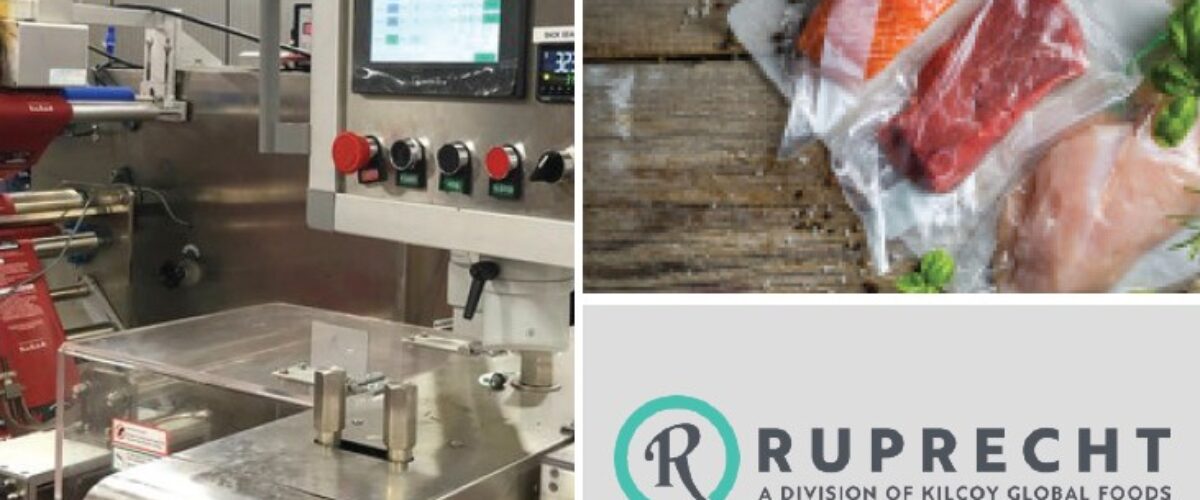

CASE STUDY: Gaining Real-time Visibility of Production Processes at Ruprecht

Ruprecht, a division of Kilcoy Pastoral Company, is a solutions-driven meat processor and food manufacturer serving both domestic and international customers in the foodservice and retail sectors in the USA. The company processes 35 million lbs. of raw proteins and fully cooked entrees delivered as branded goods.

The Challenges

Ruprecht produces perishable products for other companies, necessitating the fulfilment of brand requirements of multiple third parties. Clear visibility of the production process and each batch within production is crucial to ensure that goods are manufactured to meet the requirements of Ruprecht’s customers. Furthermore, because they deal with a large turnover of perishable products, Ruprecht’s focus is on continual improvement in the areas of cost containment and traceability.

Ruprecht required a comprehensive and robust warehouse management and manufacturing execution system to replace their custom-written legacy software and integrate seamlessly with their ERP software. While the previous legacy warehousing software was limited to receiving and order fulfilment, the new system needed to be able to manage the entire production process and provide full visibility by revealing real-time information about production.

Ruprecht solved these problems by selecting TransLution Software. The TransLution product, together with our many years of experience in the industry, allowed us to deliver a solution to Ruprecht that not only replaced their legacy systems, but also follows industry standards and best practises and is adapted to their operations. TransLution has provided the visibility and traceability Ruprecht required for full oversight of operations.

Ruprecht faced a number of additional challenges based on the nature of their business. As food producers for restaurants and chain stores, use-by and expiry dates are critical, and all processes needed to work within those constraints. Very often product needs to be shipped 7-14 days before the Best Before date and TransLution was able to help Ruprecht manage these requirements.

Receipting and shipping at Ruprecht are done through the same physical docking area which means that all receiving must be completed on tight deadlines between 11pm and 6am. The docking area is then cleaned and used for dispatch. TransLution’s flexibility fully supports the management of physical constraints such as these.

The Implementation

TransLution was implemented across Ruprecht’s facility to track material through receiving, production and dispatch, to track quality information, and to update the ERP software in real time with this information. This required the implementation team to work closely with Ruprecht, not only to implement TransLution, but also to configure the ERP software to achieve the required outcomes. The entire TransLution system was rolled out in a single phase to facilitate the takeover from Ruprecht’s previous legacy system.

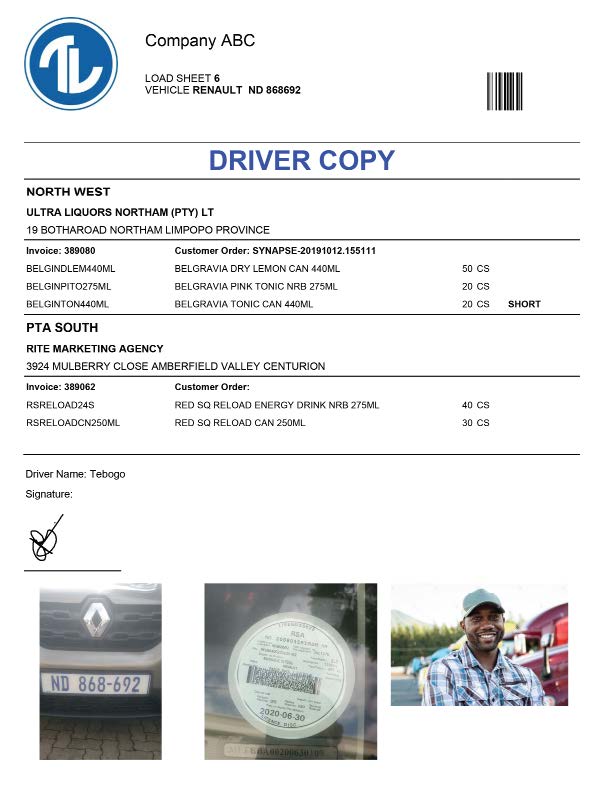

With TransLution in place, Ruprecht now can create and track Purchase Orders, Sales Orders, and Jobs to provide improved insight into productivity and material tracking. Inventory is maintained at a warehouse level in the ERP software, while TransLution controls all bins, pallets, and case-level inventory. At receiving, both Purchase Order and Transfer receipts are captured in TransLution. Visual truck inspections are performed and captured in TransLution before the stock may be received.

Ruprecht uses Android-based handheld devices that allow operators to record information about the receipt and take photos of any problems. Once the operator has recorded all the data they need, they can sign off on the inspection right there on the device. This data forms part of the TransLution process data, allowing Ruprecht to generate complete reports including photos and signatures. Each pallet is labelled and each case on the pallet is scanned to link it to the pallet. This enables tracking of material at a pallet and case level throughout the facility. Receipts are then reviewed and posted to the ERP.

TransLution manages all warehouse functions such as Put Away, Transfers, Stock Adjustments and Cycle Counts. Scanners are used to facilitate these transactions and the ERP software is updated in real time. TransLution also manages the flow of transactions, requiring operators to record each step in the process in sequence – if they skip a step, they are not permitted to proceed to the next one. TransLution can be engineered to fit existing work processes, allowing the system to work the way the operators are used to. Maintaining simplicity for operators and moving any complexity into the background where it is dealt with by the software is key to ensuring a successful uptake of such a significant implementation.

TransLution is used throughout production to keep track of material used and produced. Stock is picked for a job and then issued to the line when it is used. The quantity produced on each job operation is captured in real time, providing visibility of each job’s progress. This visibility is largely due to the implementation of EazyWeigh at each step of the production process – throughout the cooking and protein preparation process batches are weighed to determine the yield. This constant weighing process at each stage in production and at the end of the job allows management to see exactly what the losses and gains were and where they occurred.

EazyWeigh is also used at the end of the production line to automatically capture the case weight and print a case label. Cases are then palletized and the pallets are receipted against the job.

Another challenge unique to Ruprecht is the complexity of their routing. While individual routing and production for each product is not complicated, there are many variations on each product. In a single day, Ruprecht could manufacture 20-30 products, many of which share production steps.

TransLution’s ability to integrate seamlessly with scales and production equipment such as water bath cookers and timers, combined with the extensive experience of the TranLution implementation team, is what made this possible. During Dispatch, pallets are picked from the warehouse for Sales Orders using TransLution. Orders are first released to the warehouse by a supervisor. The material handler is then guided through the warehouse by the scanner and instructed on which pallets to pick for the order. Orders are then added to a load and scanned onto a truck.

The Outcome

Due to the seamless integration with, and optimization of, their ERP software, the greatest benefit for Ruprecht has been gaining full visibility and traceability through their production process. They know, in real-time, when raw materials are used, what each job’s progress is, and when stock is produced. They also know exactly how much stock is consumed and produced on a job so they can calculate gains and losses and manage yield more effectively.

In line with their company ethos of continuous improvement, since the initial implementation Ruprecht is now planning on implementing Labor Tracking for an additional layer of visibility into production processes.

About

Ruprecht

Ruprecht is a solutions-driven meat processor and food manufacturer serving both domestic and international customers in the foodservice and retail sectors. Established in 1860, Ruprecht is currently the oldest operating beef processor in the Chicago area.

Over the last 10 years, Ruprecht has experienced rapid expansion and growth due to its investment in Research and Development. Ruprecht’s expanded focus within fully cooked sous vide meal solutions, side dishes, and other value-add raw items has led this growth. While many things have changed since 1860, Ruprecht’s mission to providing the highest quality products to our customers remains our steadfast commitment. Today, these customers include well-known independent restaurants, local and national chains, national and international distributors, and retail supermarkets and wholesale clubs.

TransLution™ Software

TransLution Software, based in Atlanta, Georgia, focusses on assisting clients to automate manufacturing and distribution processes to achieve improved stock accuracy and optimize productivity. We pride ourselves on our understanding of the unique operational and stock movement processes in our customers’ businesses, as well as their relationship to financial management and control issues. TransLution Software integrates seamlessly with ERP software, business systems and production equipment, enabling the collection and presentation of shop-floor data in real time, as well as the automation of warehouse and production functions.

TransLution Software is made available worldwide through a global network of specialist implementers and resellers, working together to ensure great results. The knowledge, commitment, and depth of experience of our team enable us to tailor effective solutions to add maximum value. We have over 300 clients and have been helping manufacturing clients automate and digitize their businesses in N. America, Europe, Africa and Australia since 2002.